Finished AOI

Features

· Precise numerical control integrated surface RGB shadowless light source

· All imported 10 million-pixel industrial cameras and lenses

· The equipment structure is highly integrated, easy to install and maintain, and the interface is easy to operate

· Online detection, seamless connection with production line MES

· The three-color algorithm truly restores the color of the cells and realizes high-precision color sorting of the cells

· Artificial intelligence technology realizes battery defect classification

· Big data analysis of defect distribution and defect cell distribution

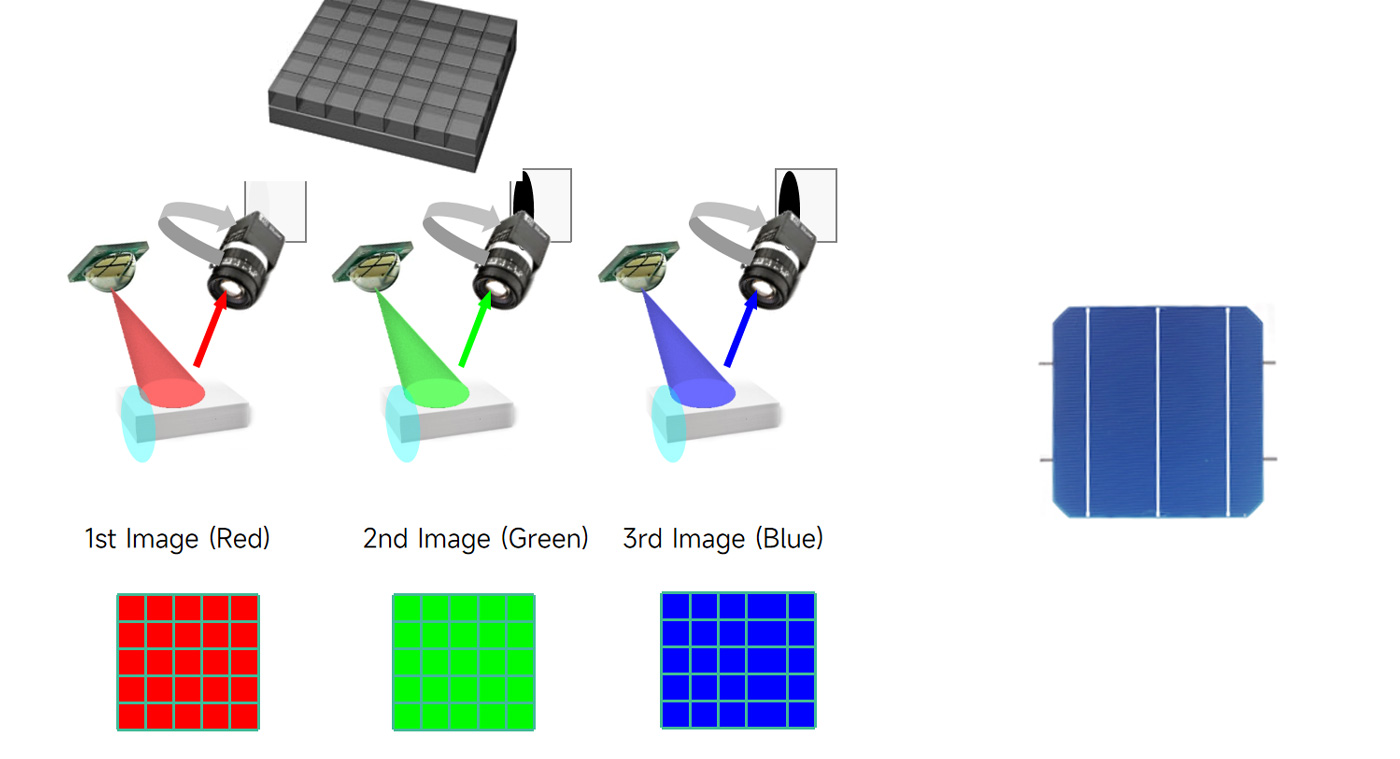

Color imaging solution: use black and white CCD chip + RGB light source (same as GP)

· The number of red, green and blue photosensitive pixels is 25 million

· True color reproduction, high sensitivity, good contrast

· Natural black and white mode, more accurate color inspection and more advantages in defect detection

· Imaging is not affected by the color temperature of the light source (or ambient light)

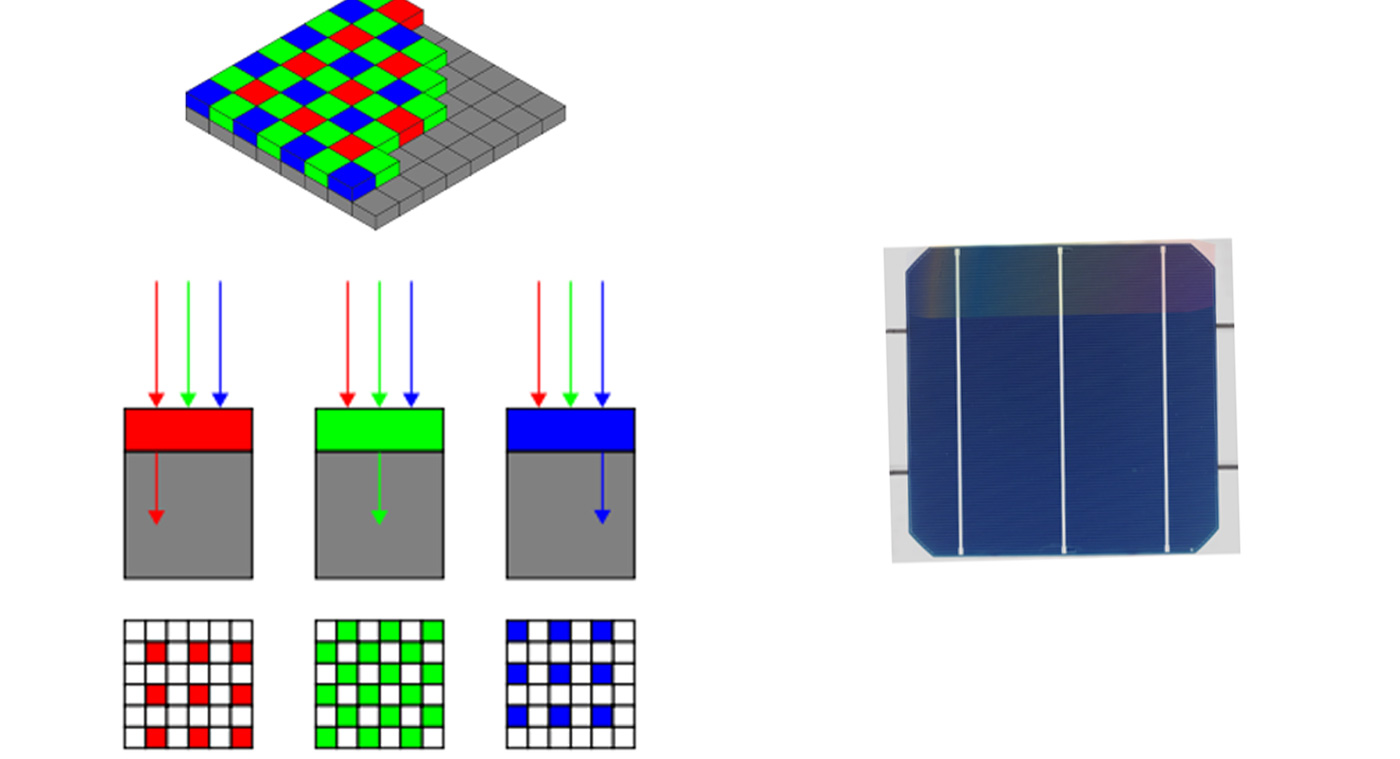

Other competing imaging solutions: use color CCD chip + white light source

· Colors are formed by interpolation, not truecolor

· The number of red and blue photosensitive pixels accounts for 25%, which is equivalent to 6 million

· The number of green light-sensitive pixels accounts for 50%, which is equivalent to 12 million

· The color is not bright enough, and the color gamut is limited

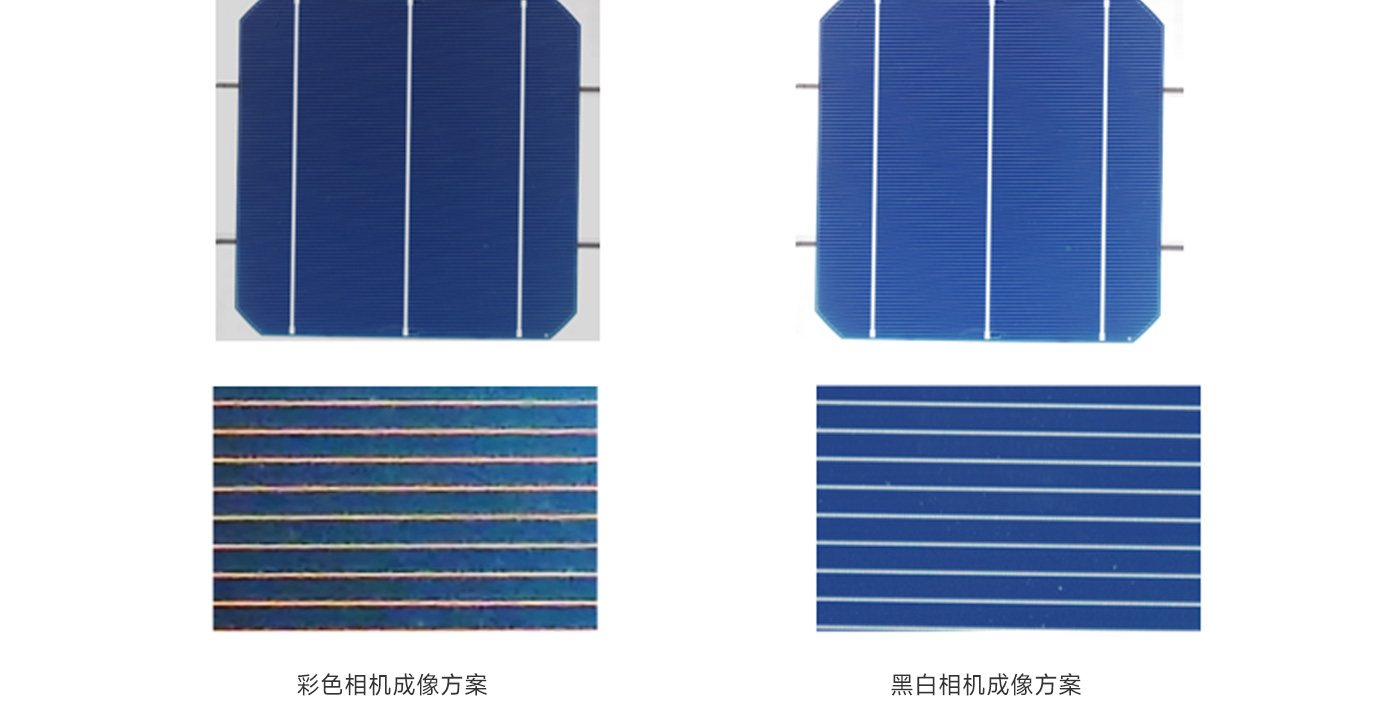

Imaging effect & comparison of advantages and disadvantages

Plan | Three-color light + black and white camera | Monochromatic light + color camera |

| Number of photos | 3 photos | 1 photo |

| CT (photographing + processing) | 850ms | 600ms |

| Treatment (color, shape, graphics, defects) | Synchronous processing, CT does not increase with detection items | Serial processing, type increase CT increase |

| Algorithm | Ruili color, accurate sorting: easy to detect surface contamination under red light (such as watermarks) | The color is not bright enough, and the slight surface contamination cannot be recognized |

| Process convenience | Product switching without changing the underlying algorithm | Product switching needs to change the underlying algorithm |

Device parameters

| Project | Specification |

Equipment ruler | Length 430mm Width 390mm Height 780mm |

| Applicable Wafer Size | 156*156mm- 170*170mm |

| Applicable Wafer Type | Monocrystalline, polycrystalline, diamond wire monocrystalline, polycrystalline, PERC cells |

| Production capacity | Up to 3800PCS/hour |

| Front camera pixels/resolution | 25 million, 34um |

| Rear Camera Pixels/Resolution | 20 million, 48um (optional 25 million configuration for easy product upgrade) |

| UPTime | >99% |

| False positive rate | As low as <1% |

False negative rate | As low as <0.1 |

| Fragmentation rate | 0% |

| Test items | defect type |

| size measurement | Side lengths, bends, diagonals, etc. |

| Damage detection | Damage, edge chipping, missing corners, grid line damage, cracks, etc. |

| printing offset | Including overall offset, grid line offset, main grid offset, etc. |

| Grid detection | Including broken grid, thinning, thickening, twisting, virtual printing, etc. |

| Dirt detection | Contains fingerprints, watermarks, screen dirt, etc. |

| Spot detection | Bright blue spots, small spots, white spots, dark red spots, slurry leakage, fingerprints, dripping oil, uncoated, diffusion boat prints, etch stains, etc. |

Line Mark Detection | The grid line becomes thicker at the position where the scratch-like defect appears on the grid line |

overshoot detection | Excessive etching on the surface of the product causes dark yellow or dark red color difference |

Color difference detection | Single chip color difference, black silk chip, flower chip, light and dark chip, intra-chip color difference |

| Test items | defect type |

| size measurement | Side lengths, bends, diagonals, etc. |

| electrode offset | Including up and down offset, left and right offset, etc. |

Electrode detection | Including electrode missing, damaged, warped, etc. |

| Dirt detection | Contains stains, fingerprints, oil stains, etc. |

| Spot detection | macula, plaque etc. |

Color difference detection | In-chip chromatic aberration, yellowing, etc. |

日韩元码一老牛影视|青青青青青精品|av在线面费网|亚洲电影有码|草比AV|免费看黄色片子|欧美成人黄色片

日韩元码一老牛影视|青青青青青精品|av在线面费网|亚洲电影有码|草比AV|免费看黄色片子|欧美成人黄色片